Engineers at the University of Maryland at College Park have found a way to improve the physical properties of wood. After a certain treatment, the material in terms of strength and rigidity can compete with steel, titanium alloy, carbon fiber, but at the same time it remains light and cheap. The research results are published in the journal Nature.

"The new way of processing wood makes it 12 times stronger than conventional wood and 10 times more rigid," said research team leader Liangbin Hu. As the second head of the survey, Teng Li, notes, in nature, the combination of these two qualities is practically not found.

“The new wood is as strong as steel but six times lighter,” says Teng Li. "And it takes 10 times more energy to break it down when compared to natural wood." Scientists even tested their own invention for bullet-penetration: if a natural sample was pierced through by a bullet, then the processed piece was only damaged.

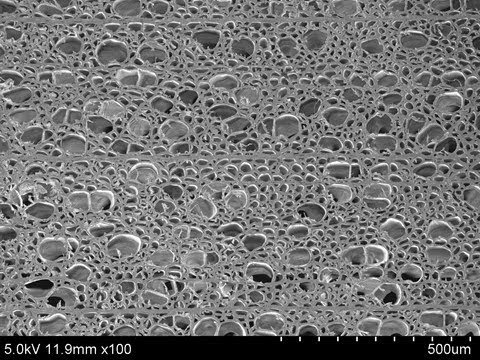

The secret of improving the material consists in two-part processing: first, the wood is "boiled" in a solution of sodium hydroxide and sodium sulfite, due to which it is partially cleaned of lignin (a polymer compound in the plant cell wall that serves as a natural binding element) and hemicellulose (a polysaccharide that strengthens the cell wall); the cellulose remains "unharmed". This is followed by the stage of hot pressing, when the material is compacted due to the simultaneous application of heat and pressure - new hydrogen bonds are formed between the cellulose molecules. The researchers emphasize that this method is universal for different types of wood and is quite easy to implement.

A material with such high performance in the future has a very wide range of applications. “It can be used in cars, airplanes, buildings - wherever steel is used,” says Liangbin Hu. In addition, soft woods such as pine or balsa, which tend to grow rapidly, can be exposed to this physicochemical attack, in order to replace them - for example, in the manufacture of furniture - slow-growing species with a denser wood (teak).