In accordance with paragraph 1 of Art. 168 of the Housing Code of the Russian Federation, the country has launched a program for the overhaul of common property in apartment buildings. Among other things, it provides for the replacement of central heating risers, which are usually thick-walled steel pipes. Their replacement in Russia is usually carried out using gas or electric welding. For the residents of the house, this is wasted time, nerves and the most dangerous thing - the likelihood of a fire. Therefore, the owners of the premises often refuse to replace the pipes, postponing the solution of the problem. This is exactly the situation that arose in a 12-storey building in the Tagansky district of Moscow. However, thanks to the latest technology of cold pressing of steel pipes, we managed to get out of this situation efficiently and safely. Lyudmila V. Kalinina, the chairman of the house council, a member of the United Taganka public association and the initiator of the project, talks about the experience of using the new technology for the overhaul of the heating system.

“I am a general architect by education. All my life I have been creating and implementing projects that help people live better and more comfortable. When a major overhaul began in our house in Bernikov Lane in 2017, I decided that the tenants deserve to have the heating replacement carried out using advanced European technologies.

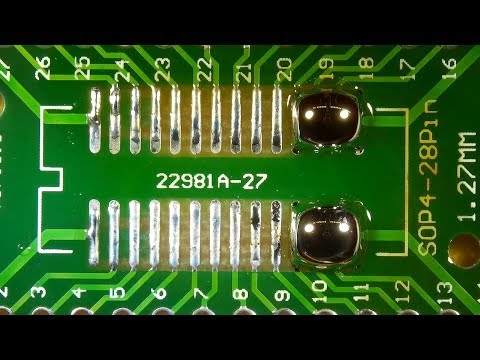

From fellow builders, I learned about the method of cold pressing of steel pipes in accordance with GOST 3262-75 *. Since in the Russian market this technology is offered only by a German company Viega, I contacted their Moscow office directly. At the Viega office, they told me in detail about the Megapress press system, showed me finished samples and photos from objects, and demonstrated the work of the press tool. For the first time Megapress was presented in Russia in 2014 at the AquaTherm exhibition. The novelty was immediately adopted by private construction companies and repair teams. But the communal services of apartment buildings, as far as I know, did not use it until 2017.

I approached the management of the Overhaul Fund (FKR) with a proposal to use Megapress instead of welding. They met us halfway and were allowed to carry out work on one riser along the entire height of the house. The result was excellent. The residents were most happy: no damage to the interior and complete fire safety. A reliable tight connection is installed in just a few seconds, and immediately after pressure testing, the pipeline is ready for full load operation!

After the analysis carried out at the technical councils in the FKR, it was decided to continue work on replacing the heating risers in the whole house using Megapress technology. Upon learning of this possibility, many residents immediately agreed to replace pipes in their apartments. Thus, our house became the first multi-storey residential building in Moscow, where, as part of a major overhaul, all central heating risers were successfully replaced using a new technology: using the Viega press system.

German quality is a guarantee of reliability during operation

In the first heating season, all Megapress connections have passed the main test: the test of time. Each Megapress fitting is equipped with an SC-Contur safety circuit, which provides guaranteed leakage during hydraulic or pneumatic testing. After detecting errors, missed fittings are quickly pressurized, and as a result, the tightness of the entire pipeline as a whole is guaranteed. Therefore, even before the start of the heating season, we knew for sure that the entire system was installed without errors and absolutely tight. Now we are preparing for the second heating season, and I am sure that it will be perfect.

My opinion, as an architect, boils down to a simple conclusion. Of course, it is necessary to use welding, but only when building new facilities or in non-residential premises. And where people have already arranged their life, it is necessary to minimize the troubles that major repairs cause. This is where Viega press technology helps.”

reference

More than 4,000 employees worldwide work for Viega Group companies, one of the leading manufacturers of engineering equipment. The assortment includes more than 17,000 items and includes equipment for plumbing and heating systems, a wide range of plumbing equipment and drainage fittings. These products are used almost everywhere: in the construction of residential and industrial buildings, in municipal utilities, as well as in shipbuilding.