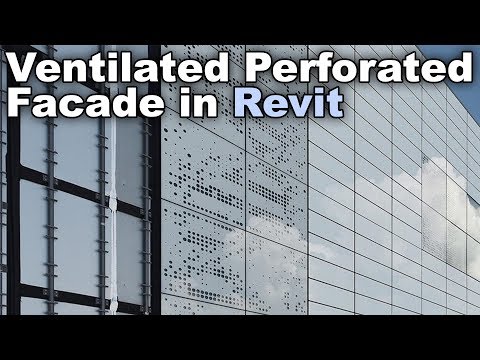

Perforated panels are made from different types of metal - aluminum, steel, galvanized iron. Perforated panels include an aluminum expanded metal sheet, which is a mesh structure with a diamond-shaped cell. It is produced in rolls, and then panels can be made from it.

The advantage of perforated panels is ease of installation, a wide range of designs; (embossed, plain and colored, with a pattern) and endless possibilities of creating expressive facades, in the perception of which chiaroscuro and the work of the surface in the light are actively involved.

Perforated panels are used for finishing the facades of new and reconstructed buildings, for full cladding of the facade or its fragments and individual parts: canopies, shutters, balcony railing …

The Rinkeby Academiy near Stockholm serves the community as a cultural center. The purpose of the institution is to create a bridge between education and business, an opportunity to prepare young people for employment.

When the old building burned down, it was decided to quickly restore it. The design was carried out by the bureau Aperto Arkitekterbyggkonsulter. Through the use of perforated aluminum panels (RMIG), the architects have created a unique image of the new building, increased security and provided protection against vandalism.

For the cladding of the building, 77 aluminum panels of 4mm thickness were used, painted on both sides in a bright lime green.

The building complex of the museum in the town of Rapperswil is more than 700 years old. In recent years, the complex has undergone large-scale restoration work and reconstruction according to the project of the Swiss architectural studio mlzd. At the end of the 13th century, a small castle complex was formed within the city walls of Rapperswil on Lake Zurich. It consisted of a watchtower and outbuildings stretching along the city wall. A number of changes were made in 1960 in order to accommodate all buildings for use as a museum and to build intermediate structures to connect with historic buildings and open galleries. Integrated into the existing complex, a new building with perforated facades is tactfully inscribed in the architectural fabric of the old city. Its façade and roof were designed in such a way that the existing windows and doors of historic buildings did not close or intersect with it.

The striking bronze façade, symbolizing the fusion of the old and the new and the administrative unification of the cities of Rapperswil and Jona, is made of Tecu Bond composite cassettes (Tecu Bond, KME Group S.p. A). Tecu Bond panels consist of two copper sheets with a polymer spacer between them. The total thickness of the plate is 4 mm.

The complex of the international headquarters of Salewa, a leader in sportswear and equipment for mountaineering (Bolzano, Italy), is formed by multifaceted volumes - rhinestone crystals. The facades are combined with perforated aluminum panels and panoramic glazing.

Materials emphasize the contrast between invisible and visible areas. According to the idea of the authors of the project - Italian architects from CINO ZUCCHI Architetti - this image symbolizes the material and non-material relations that make up the life of a modern company.

The volume of the warehouses is dressed in "leather" made of perforated aluminum panels, made in three shades of gray-blue. This tone is chosen in order to blend in with the panorama of the surrounding mountains. The same shell on the south side covers the higher office volumes and acts as sun protection.

The facades of the nine-story building for the new university campus in Bergen, Norway, were designed jointly by hlm arkitektur, Cubo arkitekter and Norwegian artist Anne-Gry Loland. The architects proposed to combine the old and the new building of the complex, creating a visual connection with the help of perforated facades. As a result, blank parts of buildings and stairwells were dressed in perforated metal panels that flicker mysteriously at dusk.

Designed by artist Anne-Gry Loland, the template consists of large symbols that come together to create a picture that is perceived from afar. RMIG has fixed its graphics in aluminum sheets using computer-controlled machines.

A few more examples of the use of perforated panels for facades: