Often, during the construction of such structures, such a speed of installation is achieved through the use of modern three-layer sandwich panels of the Metal Profile Company. They can be used in a wide variety of sizes, external curtain walls and roof structures.

It would seem that such panels have been used by builders for a long time, designers, without a fraction of a doubt, use them to create their industrial creations, and therefore they will not be able to surprise anyone with anything. However, here the Metal Profile Company was able to make another revolution - to create a unique type of fastener called SmartBOLT.

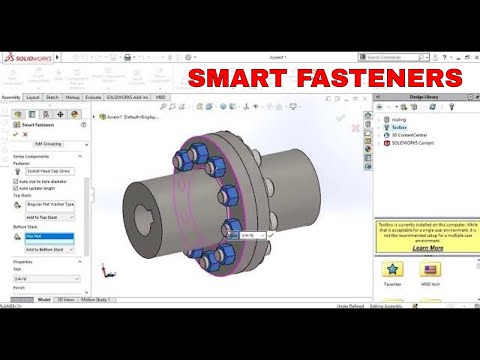

What is SmartBOLT?

The special patented SmartBOLT design provides high reliability of the three-layer sandwich panels and excellent sealing of the connection.

The unique fastener has a number of distinctive features:

- under the branded screw head with the Metal Profile Company logo, there is a special upper thread with a hemisphere, which plays an important role in the durability and reliability of the fastening;

- SmartBOLT has an aluminum washer, which has better corrosion resistance compared to standard galvanized washers;

- the fastener has two EPDM gaskets. A large gasket, located directly under the washer, has two sealing edges at once, contributing to a tighter adhesion of the self-tapping screw to the outer surface of the panel. An additional sealing layer of an EPDM gasket is located between the head and the washer of the unique bolt;

- the improved drill allows you to relieve stress in the metal when starting drilling. The maximum thickness of the metal frame, which can be supported by SmartBOLT fasteners, can be up to 14 mm;

- self-tapping screws are made of high-strength lightweight steel, which has a special corrosion-protective ceramic coating.

How is SmartBOLT fundamentally different from other types of fasteners?

Comparison of SmartBOLT with standard fasteners

Due to the fact that Metal Profile fasteners have a special upper thread with a hemisphere, the perception of wind and snow loads for sandwich panels becomes a very simple task. With the use of SmartBOLT, there is no breaking of holes in the attachment points and no unwanted gaps between the cap and the self-tapping washer. In this case, the thread supports the cladding, preventing it from missing.

As a result, when using conventional fasteners, there are often cases where water and dirt gets under the seal. This leads to inevitable corrosion of the steel cladding of the panels and the self-tapping screw itself. Also, moisture gets into the insulation, which contributes to the deterioration of its characteristics and the loss of thermal insulation properties. All this ultimately leads to a violation of the integrity of the panels.

This does not happen when using SmartBOLT, because in addition to the unique design of the upper thread with a hemisphere, a double EPDM gasket is also responsible for sealing the connection.

Often there are cases when it is not possible to tighten the self-tapping screw at a right angle. Due to the small thickness of the EPDM gasket, ordinary fasteners cannot provide a high-quality sealing of the attachment point to a three-layer sandwich panel.

Inevitably, gaps appear between the gasket and the cladding, which leads to the consequences already indicated above. If SmartBOLT for some reason is screwed at an angle to the outer side of the panel, then an additional layer of EPDM gasket will not allow moisture between the head and the self-tapping washer, and the increased thickness of the EPDM gasket with a double flange will provide a reliable tight fit.

Such a clever solution allows for high-quality and quick installation of structures, not paying attention to minor installation flaws.

Application experience and results

Despite the ambiguous views of some skeptical builders on the new development, today there are already objects where SmartBOLT fasteners have found application.

Perhaps the most unexpected result for everyone was that during the installation of three-layer sandwich panels on various frame structures with a metal thickness of up to 14 mm inclusive, only an insignificant part of the self-tapping screws showed nozzle breaks - SmartBOLT is very difficult to break! High quality fastening was guaranteed in most cases.

Thus, today in the Russian and world markets, perhaps, there is no better, more reliable and durable fastener for three-layer sandwich panels than the solution patented by Metal Profile Company called SmartBOLT.

This is really a solution in the "Smart" style for those who value their time and the time of builders who strive to deliver work on time and reduce to zero the probability of poor-quality installation, which, in turn, determines the invariability of the technical characteristics of the fixed elements of the structure and is long service life of the buildings under construction in general.

At first glance, an insignificant point regarding the choice of fasteners can significantly affect the final result. The SmartBOLT fastener provided at the design stage solves all the problems listed above associated with the operation of such buildings and makes a revolutionary technical breakthrough where it was not expected at all.